GrindNEP – preparation of cutting edges directly on

your NUMROTO tool grinding machine

Accurate preparation of cutting edges is now an essential factor in producing modern cutting tools, enabling a significant increase in tool life. Unfortunately, all solutions up to now have either required a considerable financial investment for the procurement of special machines and/or have offered little flexibility when generating the desired preparation size or a specific shape. Flexibility is very important, however, especially in the preparation of drilling tools, where an enormous variety of sizes and shapes needs to be covered.

Accurate preparation of cutting edges is now an essential factor in producing modern cutting tools, enabling a significant increase in tool life. Unfortunately, all solutions up to now have either required a considerable financial investment for the procurement of special machines and/or have offered little flexibility when generating the desired preparation size or a specific shape. Flexibility is very important, however, especially in the preparation of drilling tools, where an enormous variety of sizes and shapes needs to be covered.

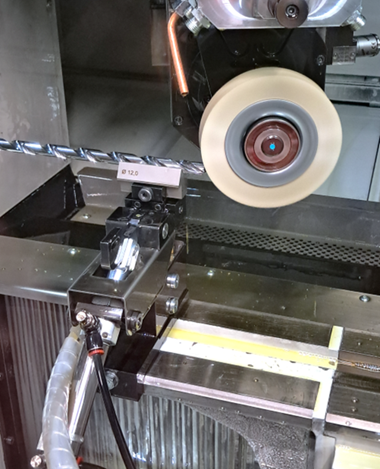

NPiTec has addressed this issue by developing GrindNEP (Grind and Edge Prep). This now enables any operator of a tool grinding machine equipped with NUMROTOplus to prepare cutting edges on drilling, milling and reaming tools in a simple, reliable and efficient manner, using a precisely controlled brushing movement. In addition to the size of the cutting edge preparation, its shape and symmetry (k-factor) can also be accurately controlled.

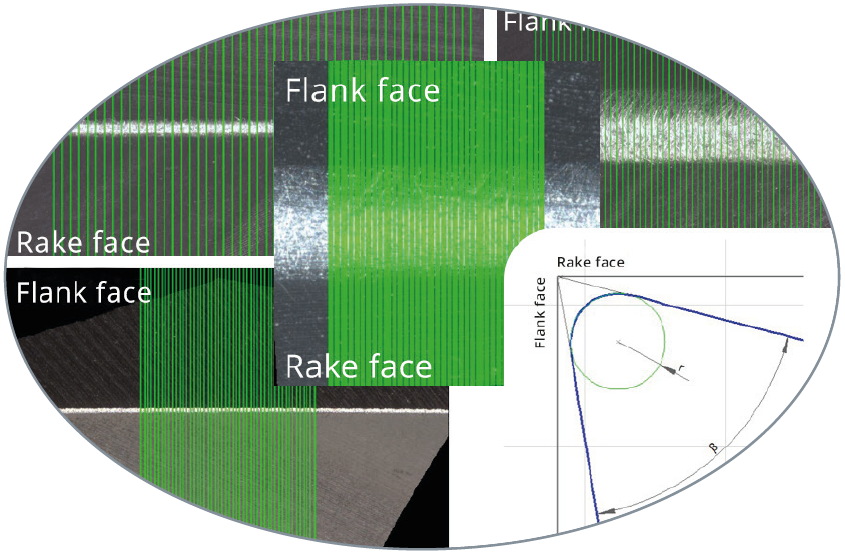

Using the ‘External Path Calculation’ interface provided by NUMROTOplus, GrindNEP retrieves all relevant geometry data from NUMROTO and displays this on a graphical user interface specially developed by NPiTec. This allows the user to adjust all relevant process parameters as well as manage programs and brushes. The calculated results are then automatically transferred to NUMROTO as a movement path that is specifically adapted for the brushing process.

With GrindNEP, NPiTec has set itself the goal of making cutting edge preparation accessible to EVERYONE, from oneperson regrinding companies to large tool manufacturers. As a customer, you benefit from regular software updates to expand functionality, combined with extensive expert knowledge and a direct contact person.

We are also pleased to assist our customers at all times with any questions they may have about measurement technology relating to cutting edge preparation.

Results

GrindNEP enables you to produce rounded edges in the range of approx. 5 to 100 μm economically, flexibly and easily. By means of the best movement path and the associated adjustment options, the shape of the rounded edges can be specifically controlled in terms of roundness and symmetry (k-factor).

Process reliability

Our wealth of expertise in the preparation of cutting edges and the use of special high-performance brushes, coupled with optimised movement control, mean that we can maximise process reliability with GrindNEP.

This process reliability forms the basis for efficient, reproducible and process-integrated preparation of cutting edges in your tool grinding machine:

Our brushes

High-performance brushes specially developed and optimised for use on CNC tool grinding machines:

- Base body with solid, stable flange and precise bore for high concentricity

- Balanced for smooth running and protection of the grinding spindle

- Reduced non-productive times through parallel

mounting on the grinding wheel package - Diamond-tipped filaments with ground ends for reliable and optimally reproducible results in edge preparation

- Batch tracking of the brushes to meet the highest

quality standards - Optional reconditioning to save costs and protect

the environment - Various versions available, depending on the intended use

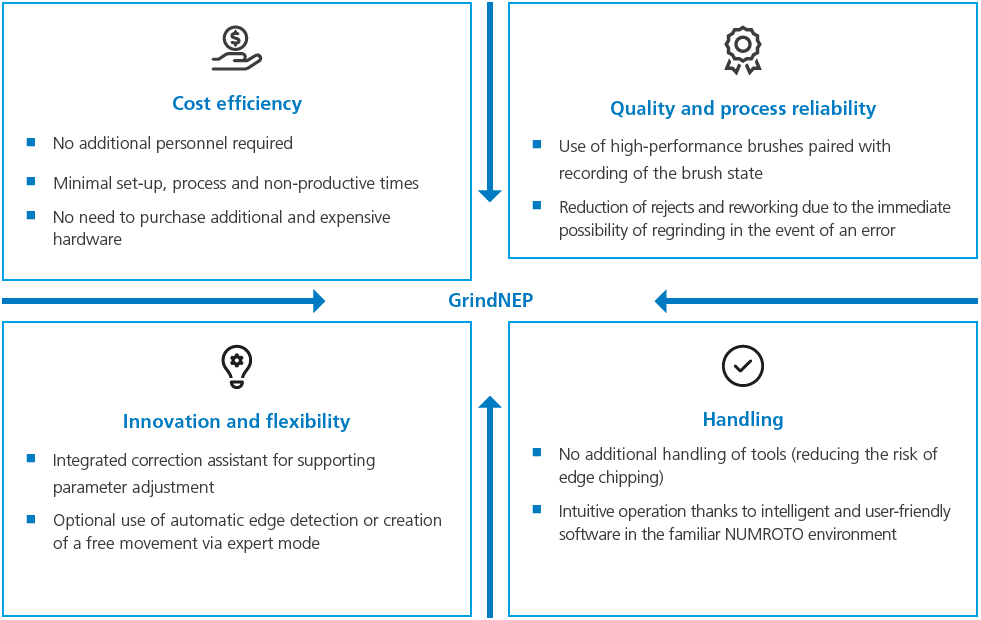

Your advantages at a glance

Prerequisites

The following technical requirements must be met in order to make full use of GrindNEP:

- NUMROTOplus version 5.0.0g or higher:

Depending on the intended use, a lower NUMROTOplus version may also be sufficient. For example, drilling tools can generally be processed from version 4.2.1g onwards. For newer versions of GrindNEP, more recent NUMROTOplus versions may also be necessary in future. We will be happy to provide you with more detailed information on the required version at any time upon request. - ‘External path calculation’ option

- ‘Interface for machine state information (Industry 4.0)’ option (only when brush management is used)

- It should be possible to set a minimum grinding spindle speed of 500 rpm

Info: The necessary NUMROTO options can usually be provided by NUM AG for testing purposes following consultation with us and in agreement with the machine manufacturer.

So, please do not hesitate to arrange a free, no-obligation testing appointment with us.